CNC Turning Parts Factories: Revolutionizing Precision Manufacturing

CNC turning parts factories are pivotal in the realm of modern manufacturing, especially when it comes to producing components with intricate precision and outstanding reliability. The advancements in technology over the years have enabled these factories to provide unmatched quality and efficiency, serving a diverse range of industries from automotive to aerospace. In this extensive article, we will dive deep into the world of CNC turning, exploring its advantages, processes, and the future it holds.

The Essence of CNC Turning

CNC, or Computer Numerical Control, is a method of automating machine tools through the use of computers executing pre-programmed sequences of machine control commands. This technology is integral in CNC turning processes, where materials are machined into specific shapes. Here’s a comprehensive look at how CNC turning works:

- Material Selection: CNC turning can be performed on various materials including metals, plastics, and composites.

- Setup: The materials are securely attached to the workpiece and correctly aligned.

- Programming: The operator inputs the specifics of the design into the CNC machine's software.

- Machining: The machine executes the program, rotating the workpiece against a cutting tool to shape the material.

- Finishing: Post-machining processes, such as polishing and coating, enhance the component's appearance and durability.

Key Benefits of CNC Turning Parts Factories

The adoption of CNC turning technology in factories offers a multitude of benefits that set them apart from traditional machining processes:

1. Enhanced Precision and Accuracy

One of the greatest advantages of cnc turning parts factories is their ability to produce components with extremely tight tolerances. The automated nature of CNC machining eliminates the potential for human error, ensuring that the parts produced are consistent and accurate to the required specifications.

2. Increased Productivity

CNC machines operate continuously, allowing for high-volume production. This capability not only speeds up the manufacturing process but also increases output, enabling businesses to meet high demand efficiently.

3. Versatility in Production

CNC turning is not limited to a single type of product. It can manufacture a wide array of complex shapes and sizes. This versatility is critical for industries that require customized solutions.

4. Cost-Effectiveness

Although the initial investment in CNC machinery can be significant, the long-term savings often outweigh these costs. With reduced waste and lower labor costs, cnc turning parts factories can operate more economically than traditional machining options.

Applications of CNC Turning Parts

CNC turning is utilized across various sectors. Below are some prominent applications:

1. Automotive Industry

Components such as gears, shafts, and brackets are commonly produced using CNC turning methods. The automotive sector demands precision and durability, making CNC turning a perfect fit.

2. Aerospace Industry

The aerospace industry often requires high-strength components that can withstand extreme conditions. CNC turning is ideal for producing parts like engine mounts and fuel systems with exacting standards.

3. Medical Equipment

The medical industry benefits from CNC turning through the creation of surgical instruments and implantable devices, where precision is critical for functionality and safety.

4. Consumer Electronics

CNC turning is also prevalent in the production of components for consumer devices such as smartphones and laptops, where intricate designs and lightweight materials are essential.

Quality Control in CNC Turning Parts Factories

Quality control is a crucial aspect of any manufacturing process, and in cnc turning parts factories, it is even more so. Here’s how quality assurance is maintained:

- Regular Calibration: CNC machines must be calibrated regularly to ensure accuracy.

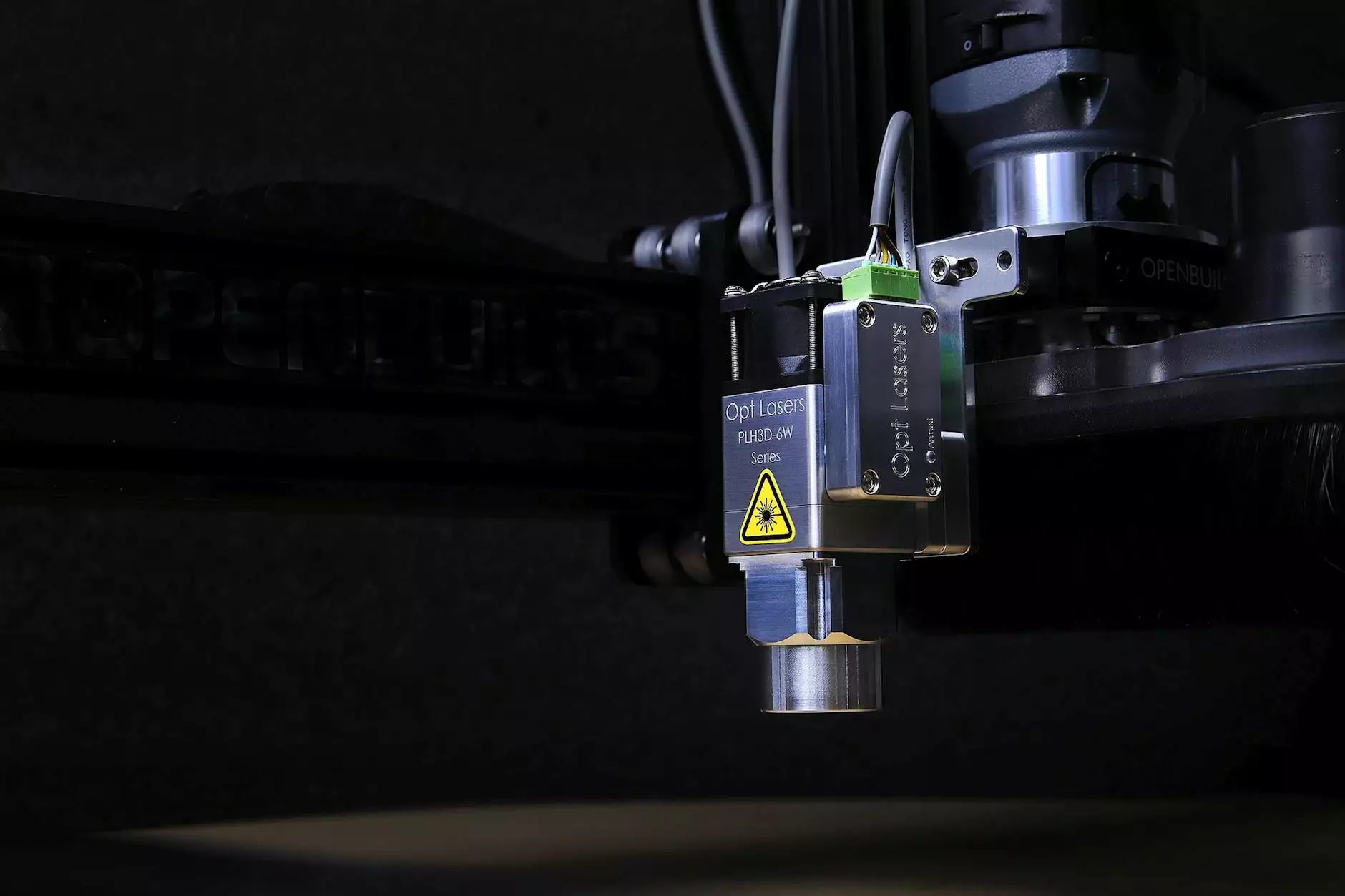

- Inspection Techniques: Techniques such as CNC probe measurement and laser scanning are employed to verify the dimensions of parts.

- Testing: Finished components undergo rigorous testing to guarantee they meet industry standards and specifications.

Emerging Trends in CNC Turning Technology

The landscape of CNC turning is ever-evolving, driven by advancements in technology and industry demands. Some of the most compelling trends include:

1. Automation and AI Integration

The integration of artificial intelligence and automation systems into CNC machining is on the rise, allowing for real-time monitoring and adjustments during the manufacturing process. This leads to optimized operations and reduced downtime.

2. Additive Manufacturing Hybrid Systems

The combination of CNC turning and additive manufacturing capabilities gives factories the ability to fabricate parts that were previously impossible to create, thus expanding design possibilities.

3. Sustainable Practices

With increasing regulations on environmental impact, many CNC turning parts factories are adopting sustainable practices, including waste reduction and energy-efficient machinery.

Choosing the Right CNC Turning Parts Factory

Selecting the right factory for CNC turning could determine your project's success. Here are factors to consider:

- Experience: Look for a factory with a proven track record in your specific industry.

- Technology: Ensure that the factory uses up-to-date CNC technology for optimal precision.

- Quality Certifications: Check for ISO certifications and adherence to quality standards.

- Customer Support: Reliable customer service can be crucial during production or if issues arise.

Conclusion

The evolution of cnc turning parts factories has undoubtedly reshaped the manufacturing landscape, bringing unparalleled precision, efficiency, and versatility to numerous industries. As technology continues to advance, so will the capabilities of these factories, paving the way for future innovations. Investing in CNC turning is not just about keeping up with industry standards; it’s about leading the charge toward excellence in manufacturing. Engaging with experts in the field will allow businesses to leverage these advancements, ensuring their place at the forefront of their respective industries.

For more information about high-quality CNC turning services, visit Deep Mould to learn how we can provide the precision and expertise your business needs.